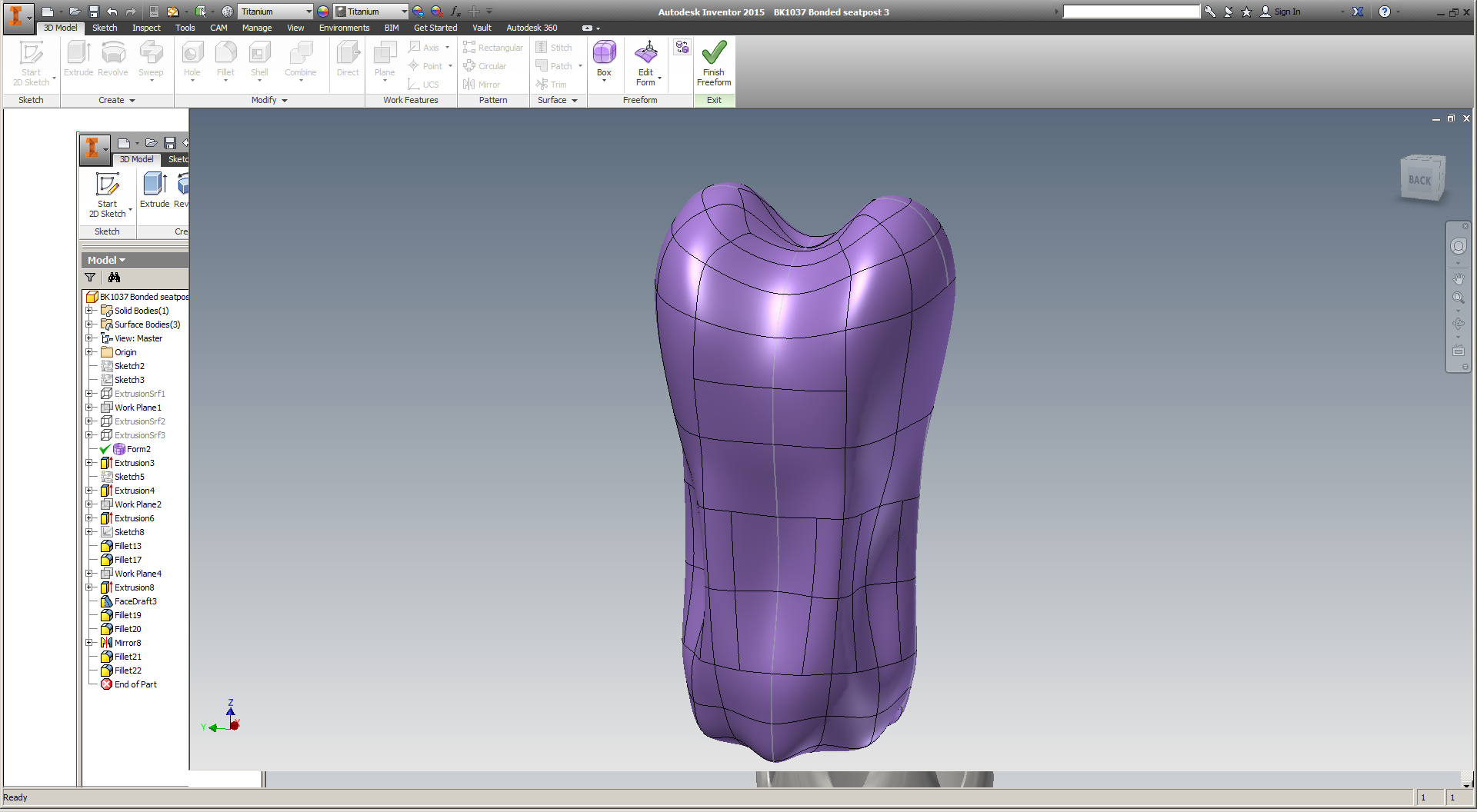

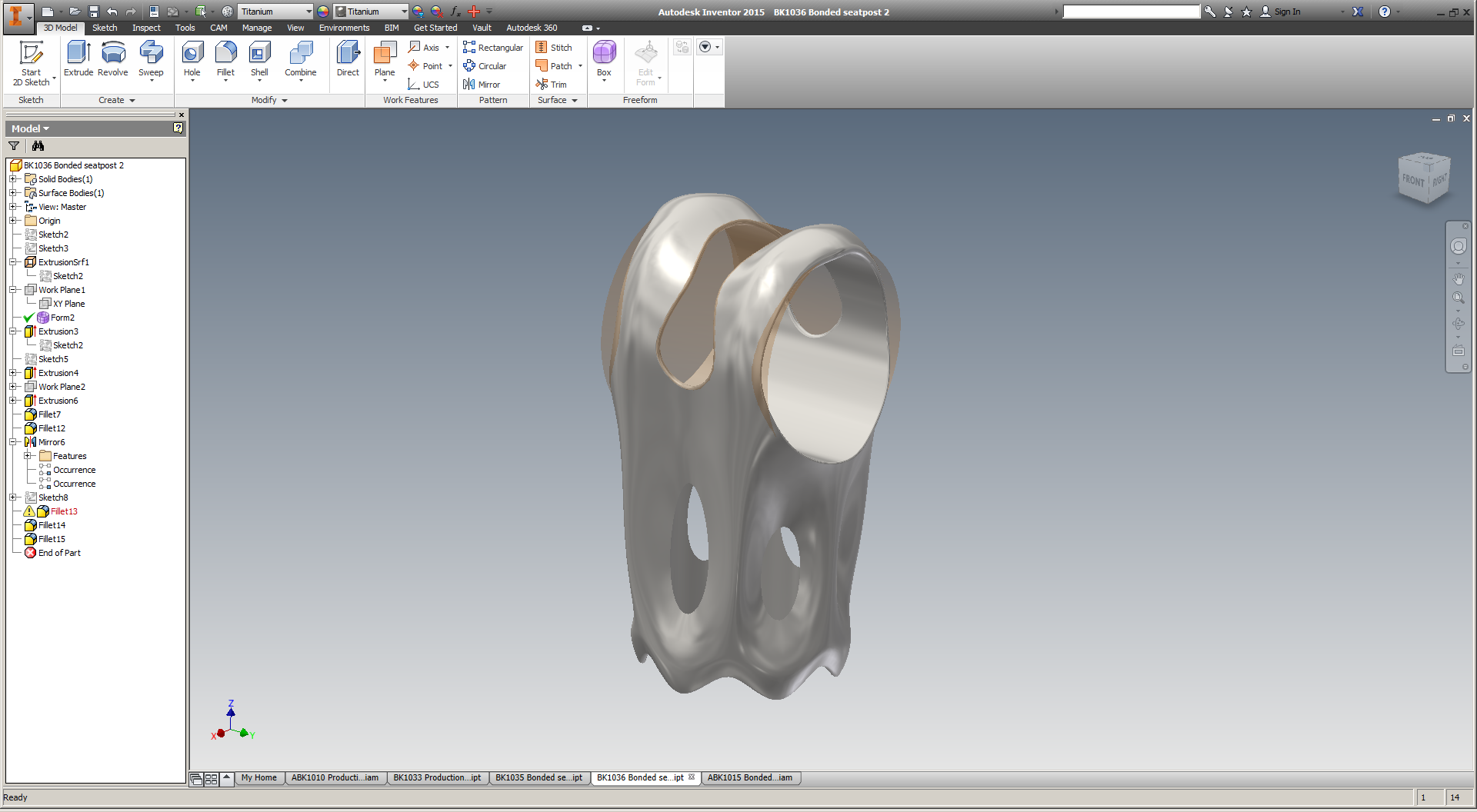

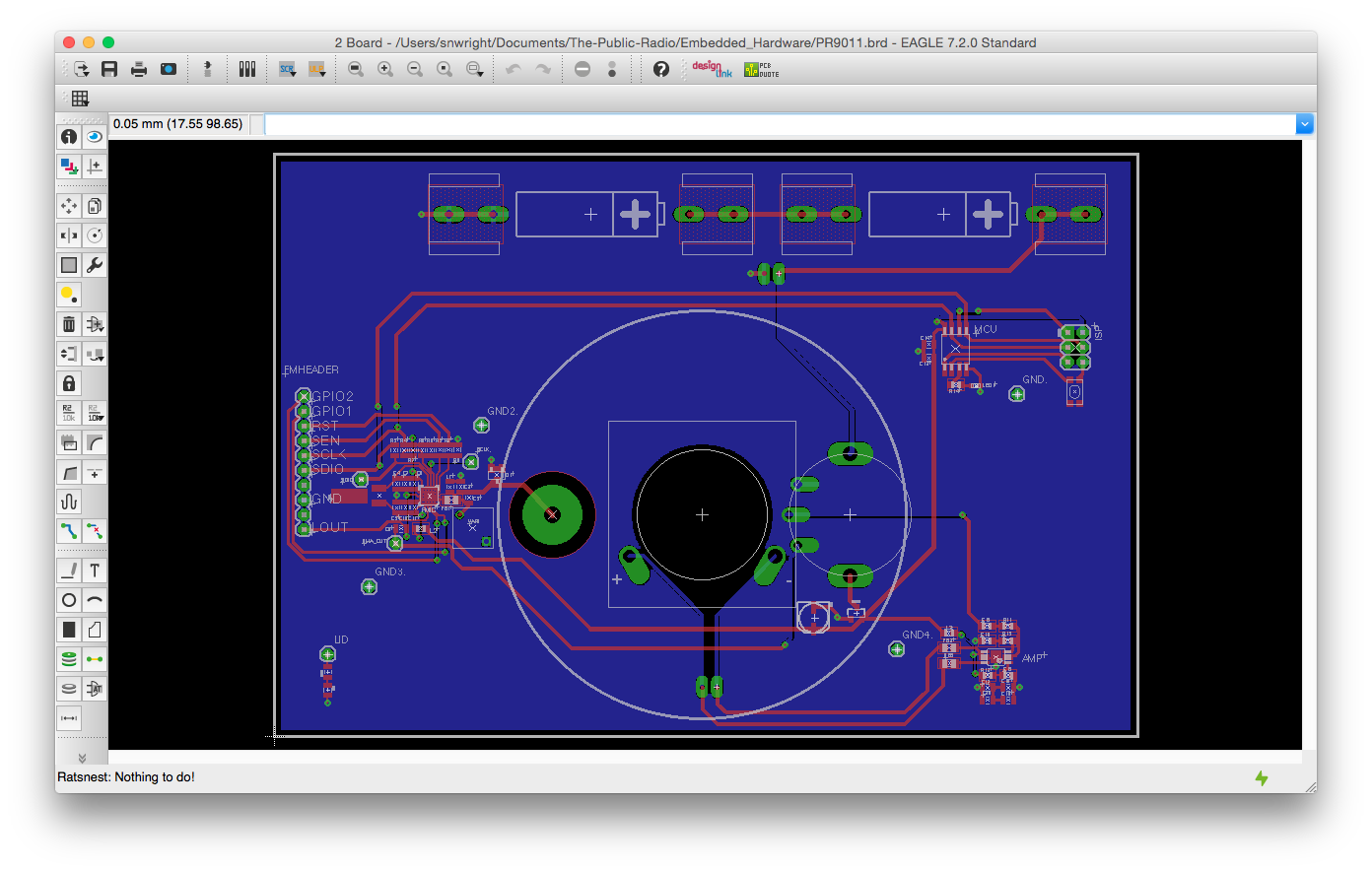

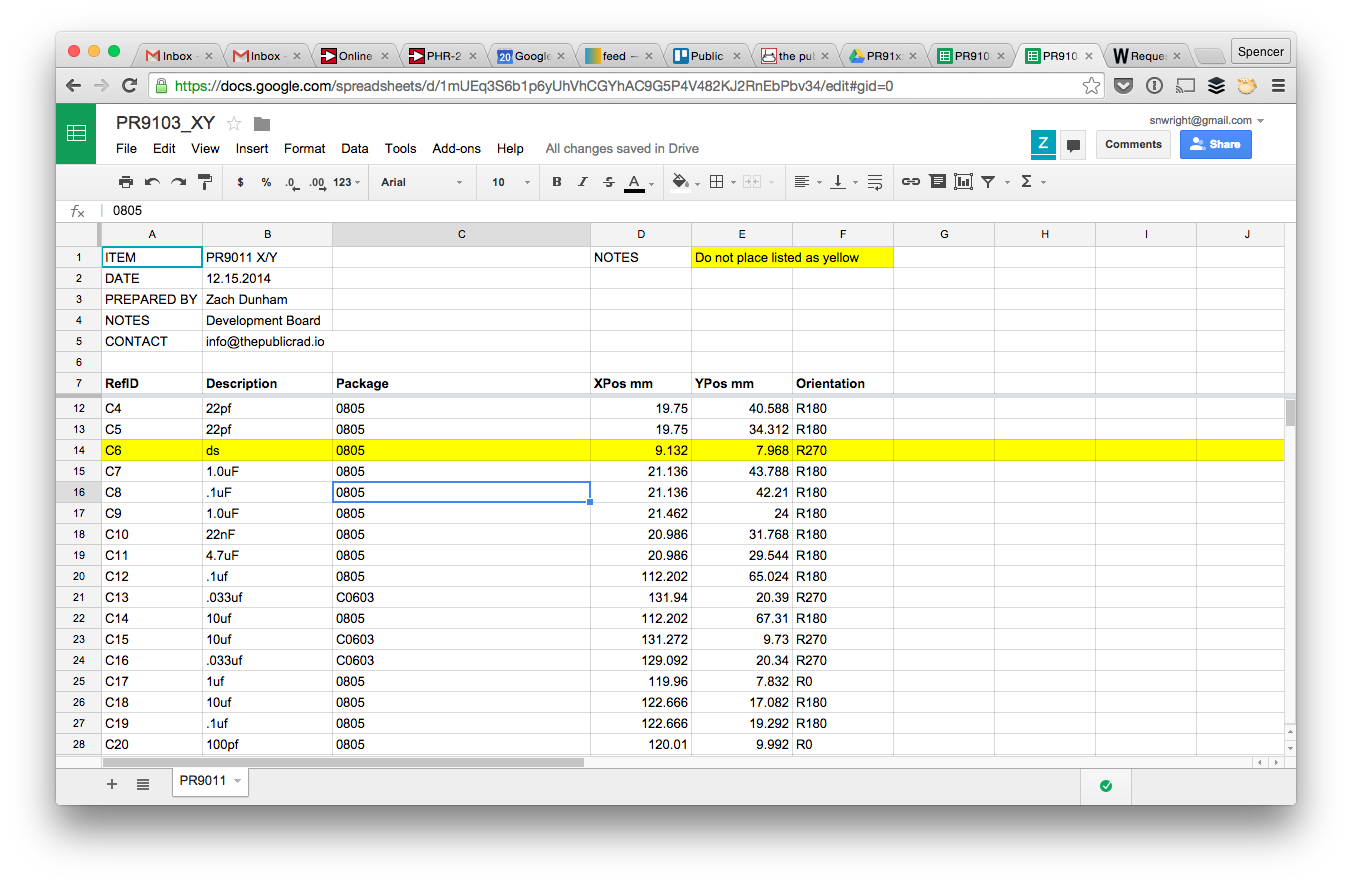

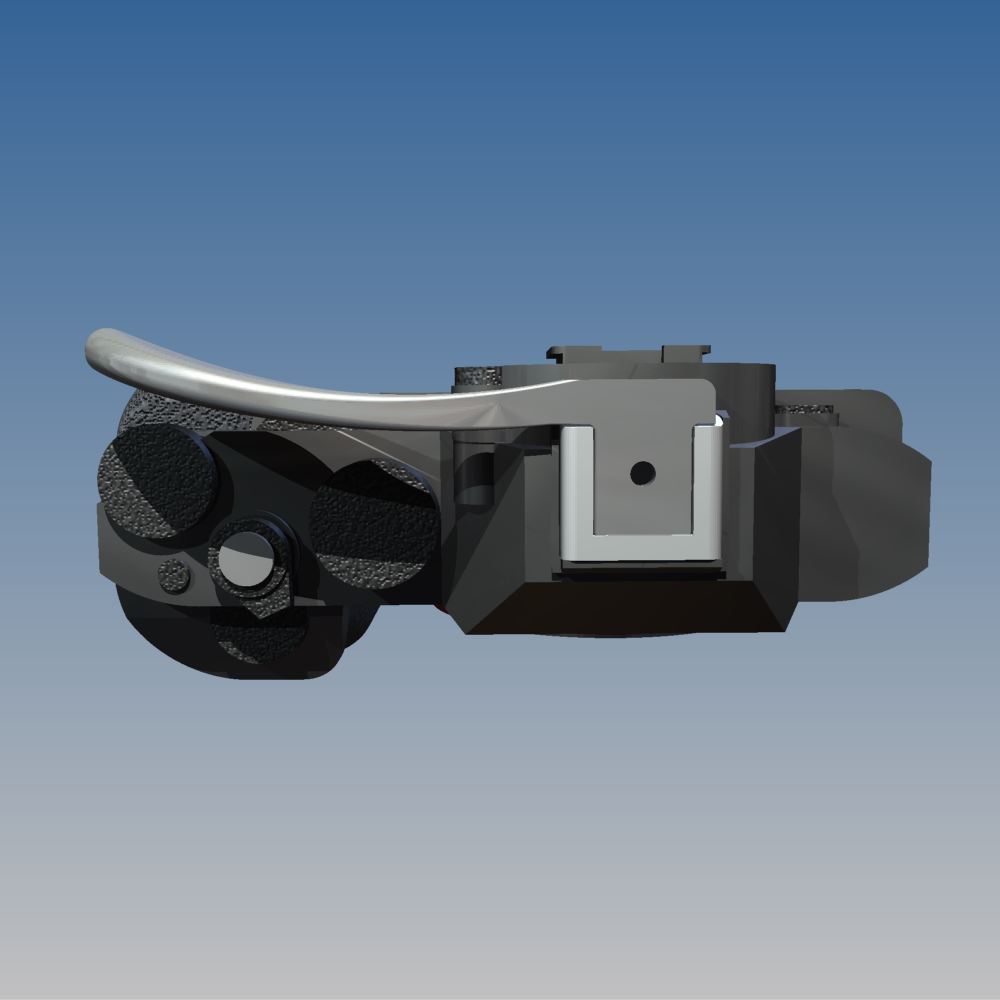

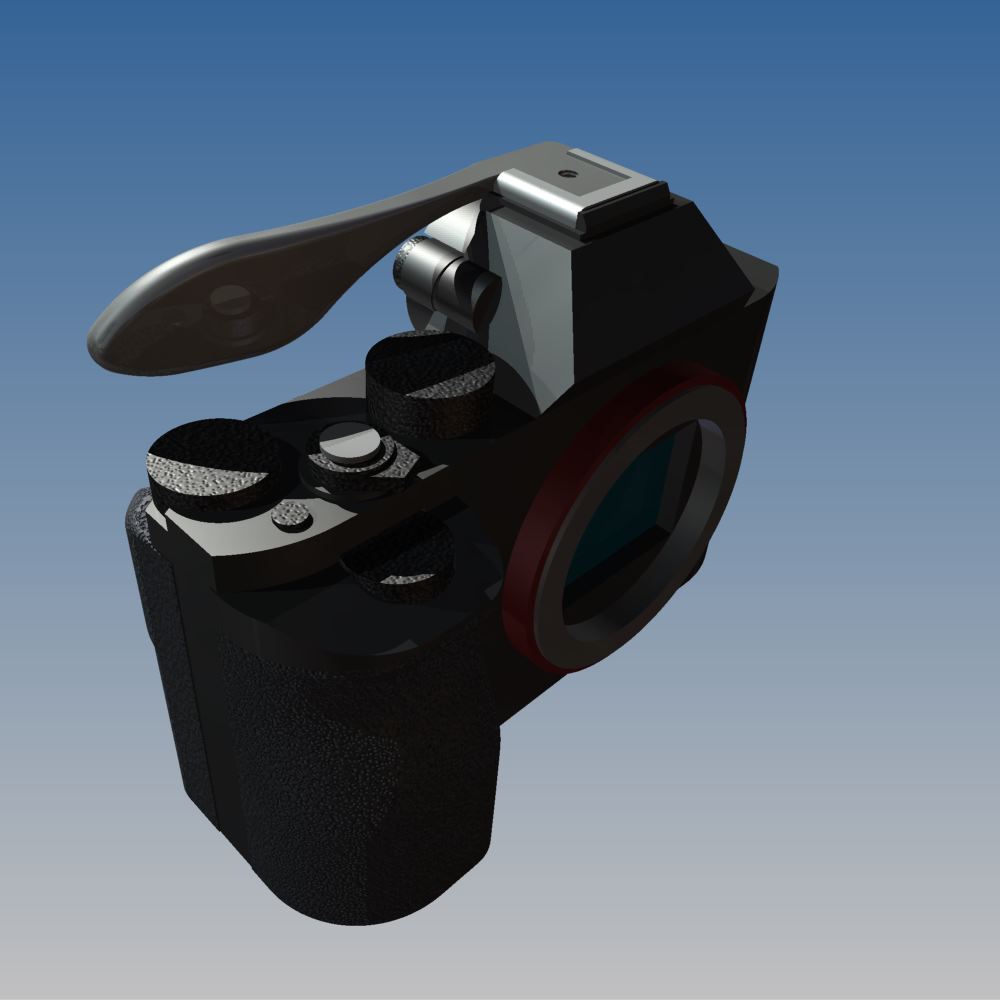

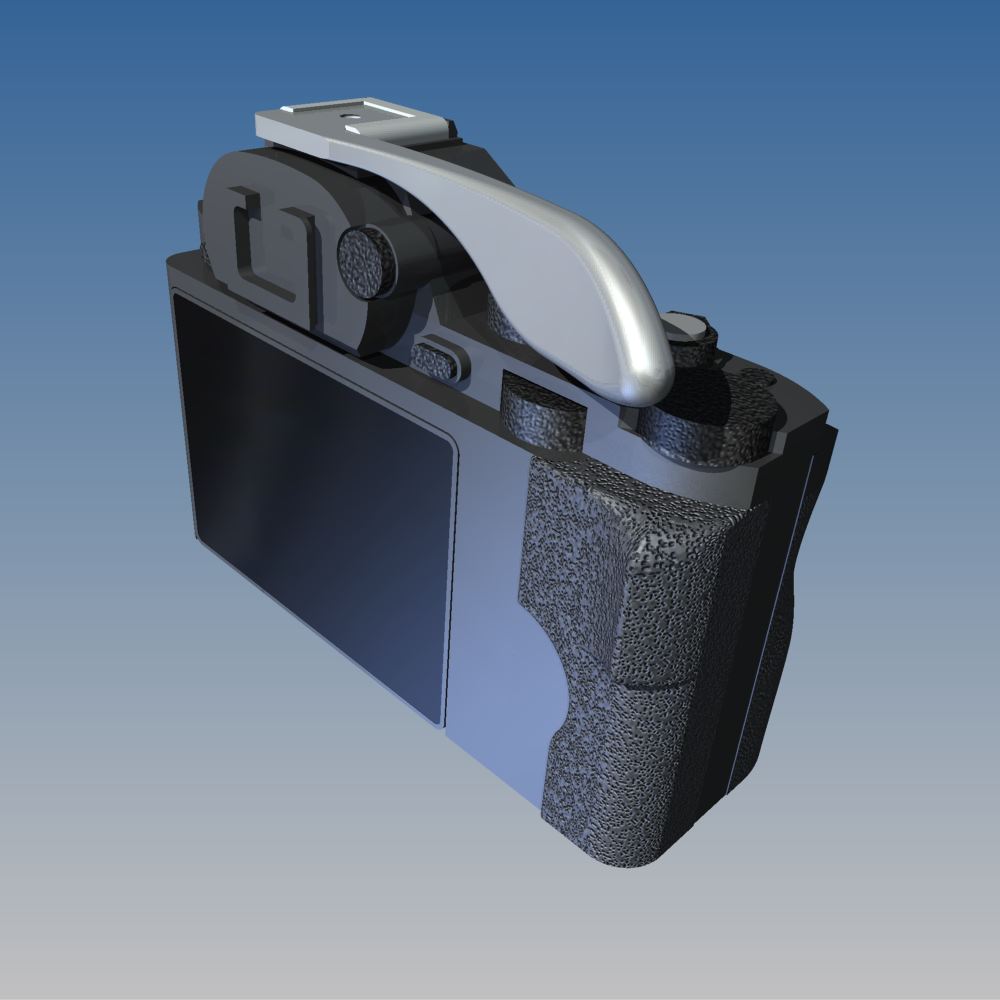

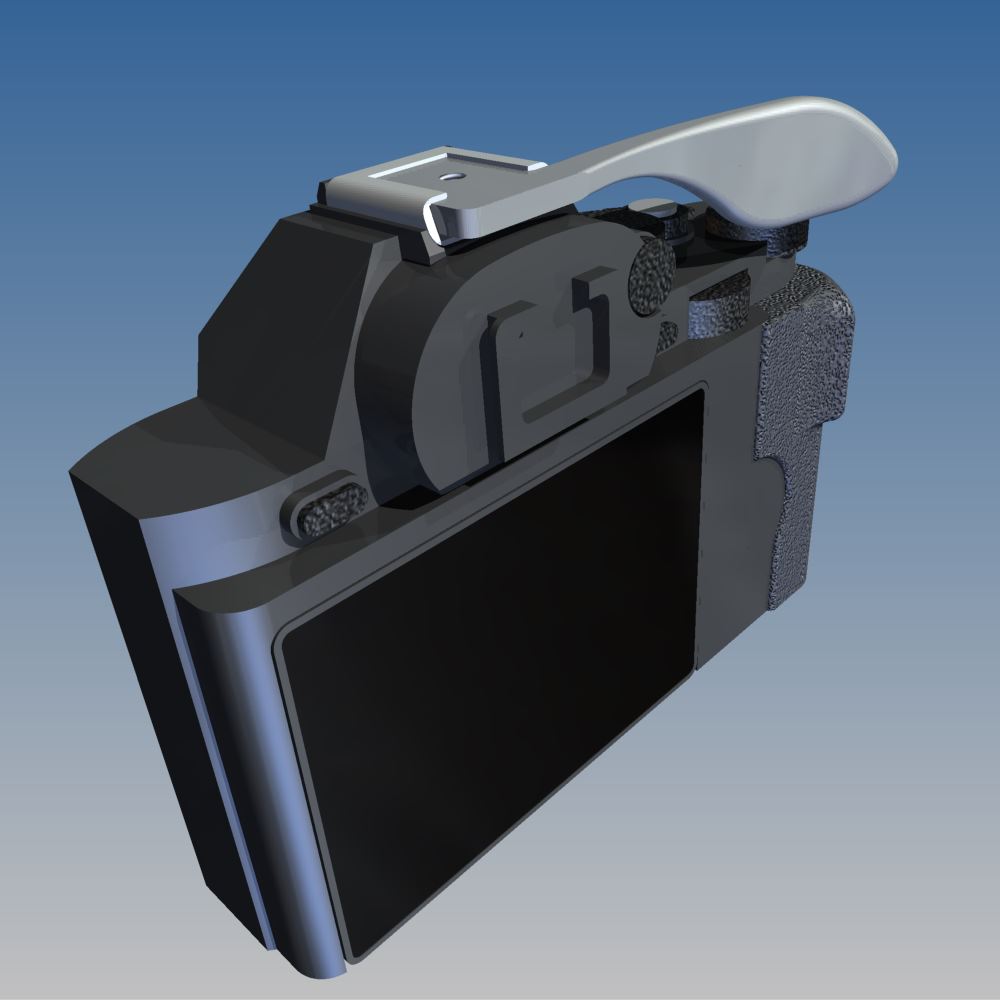

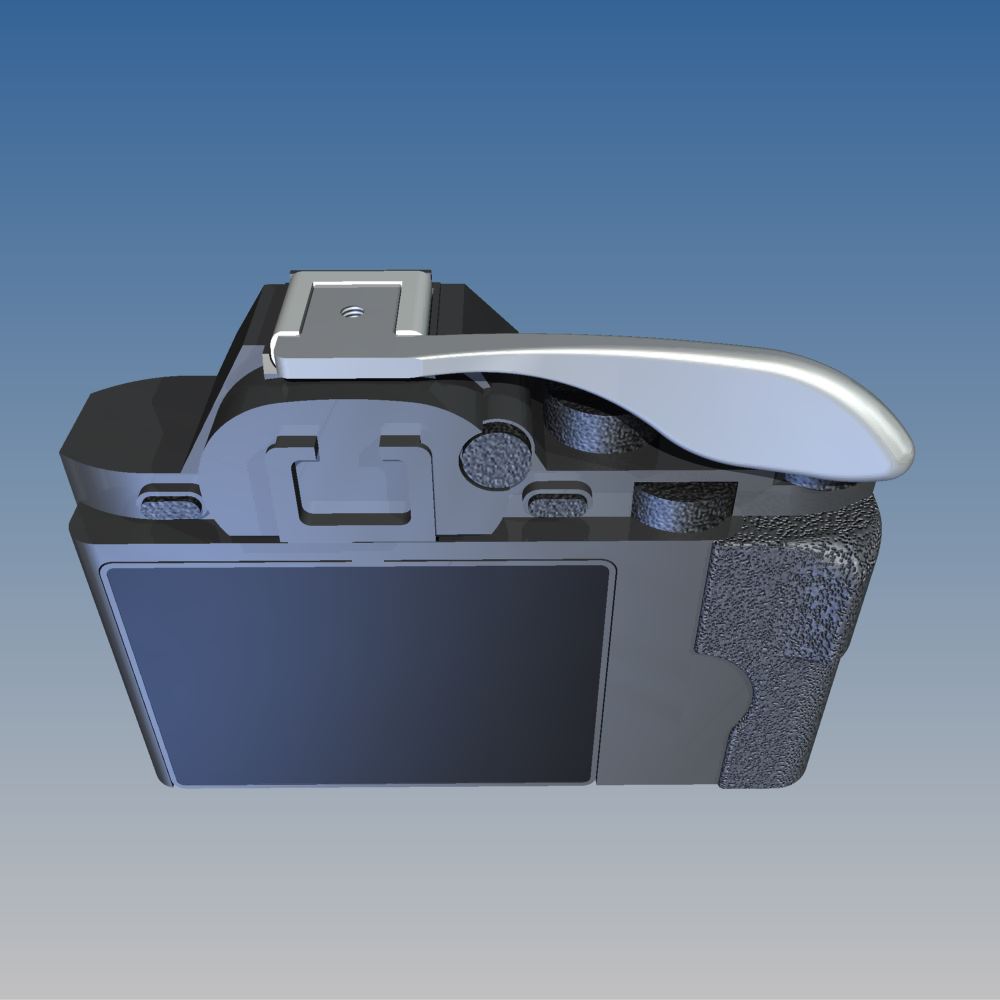

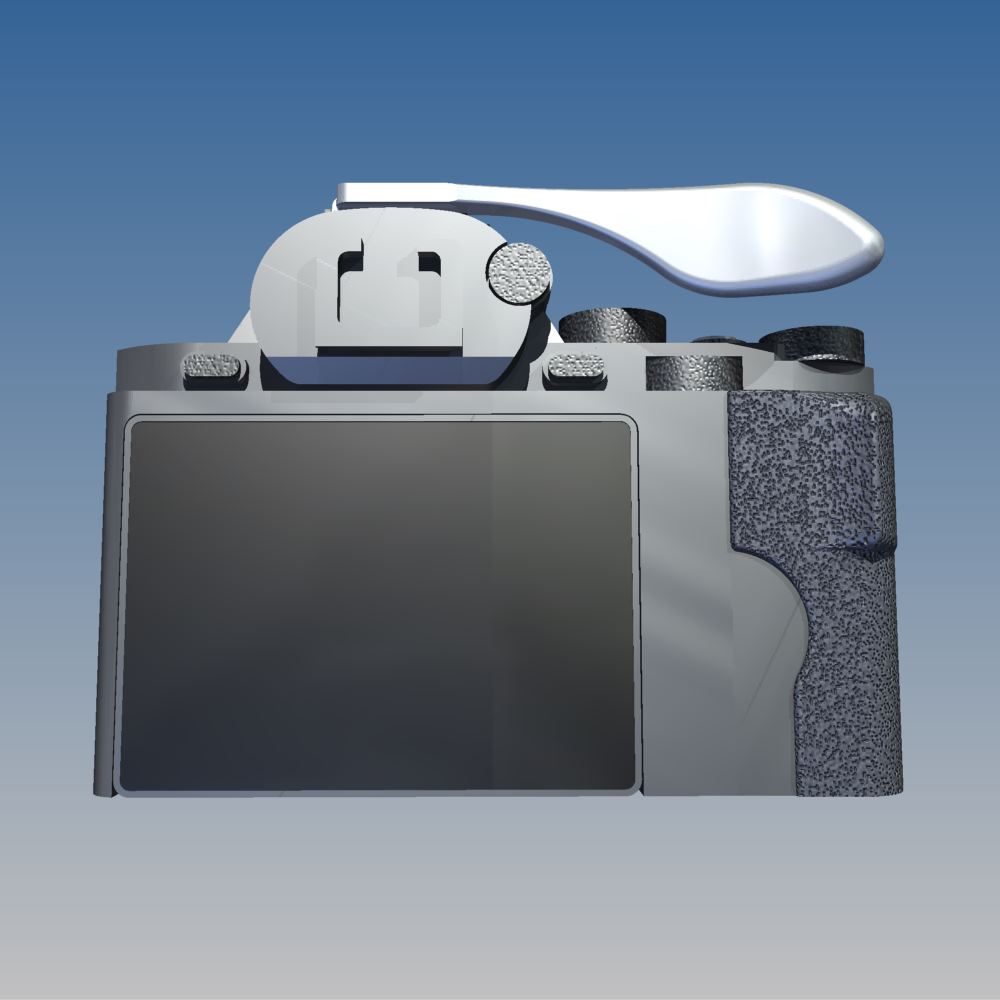

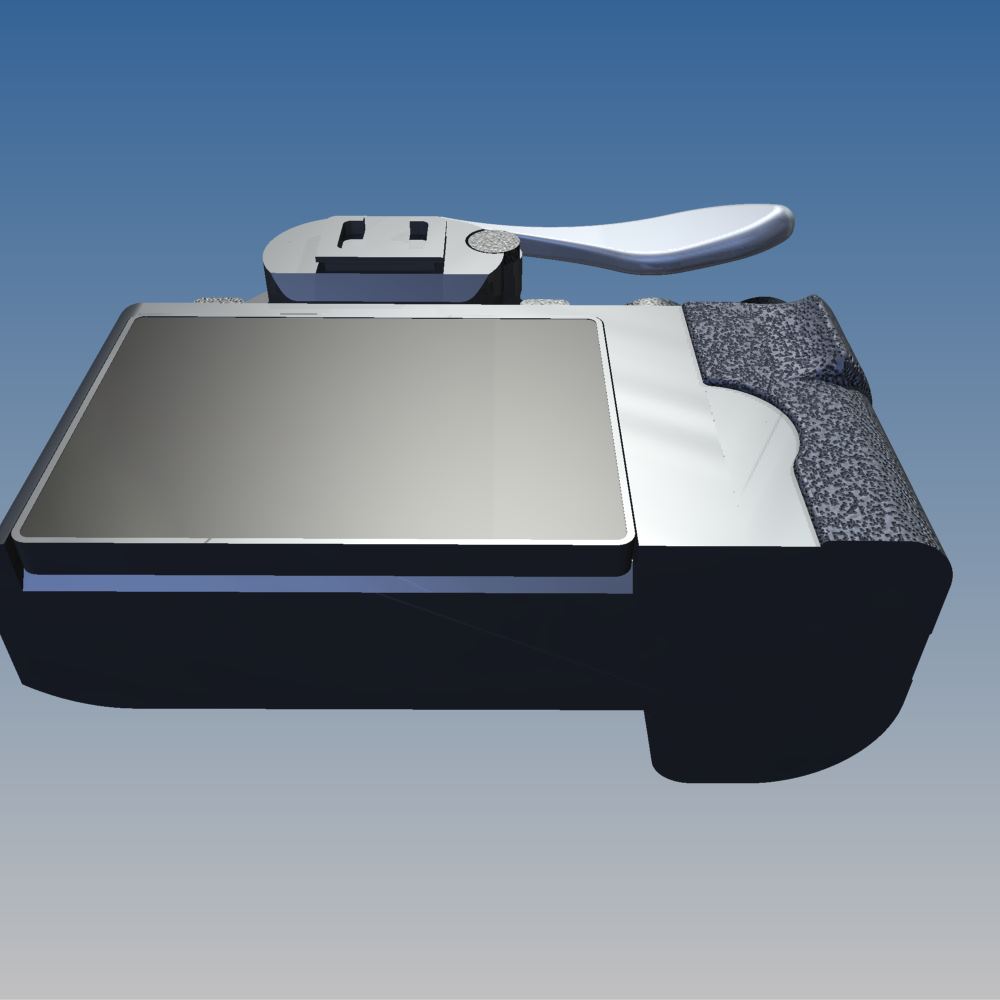

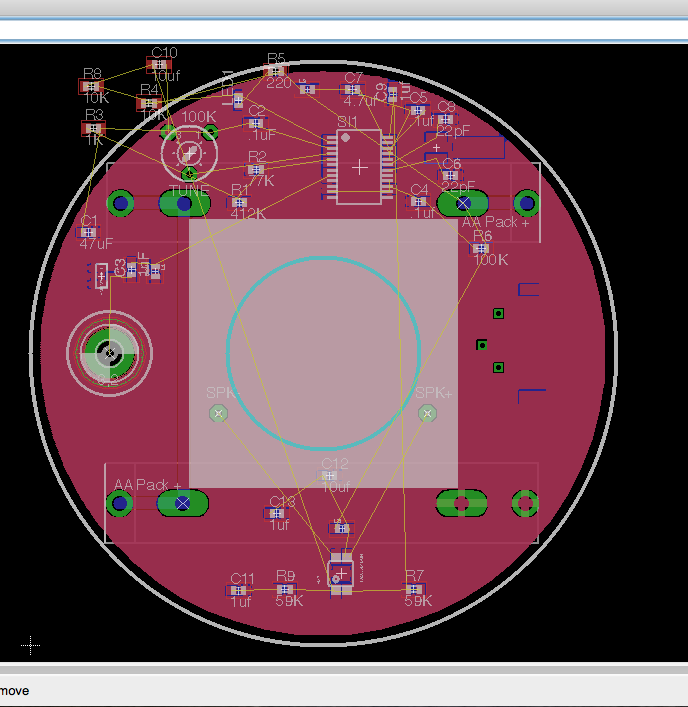

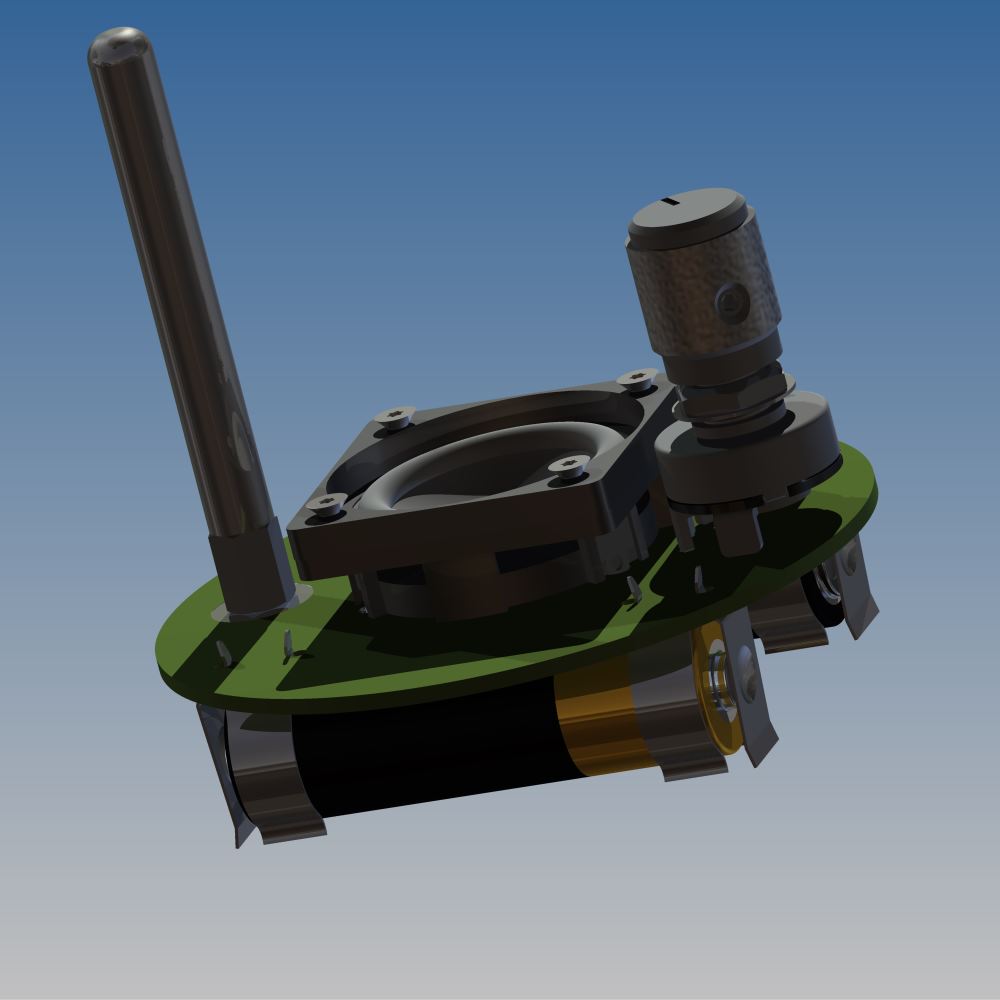

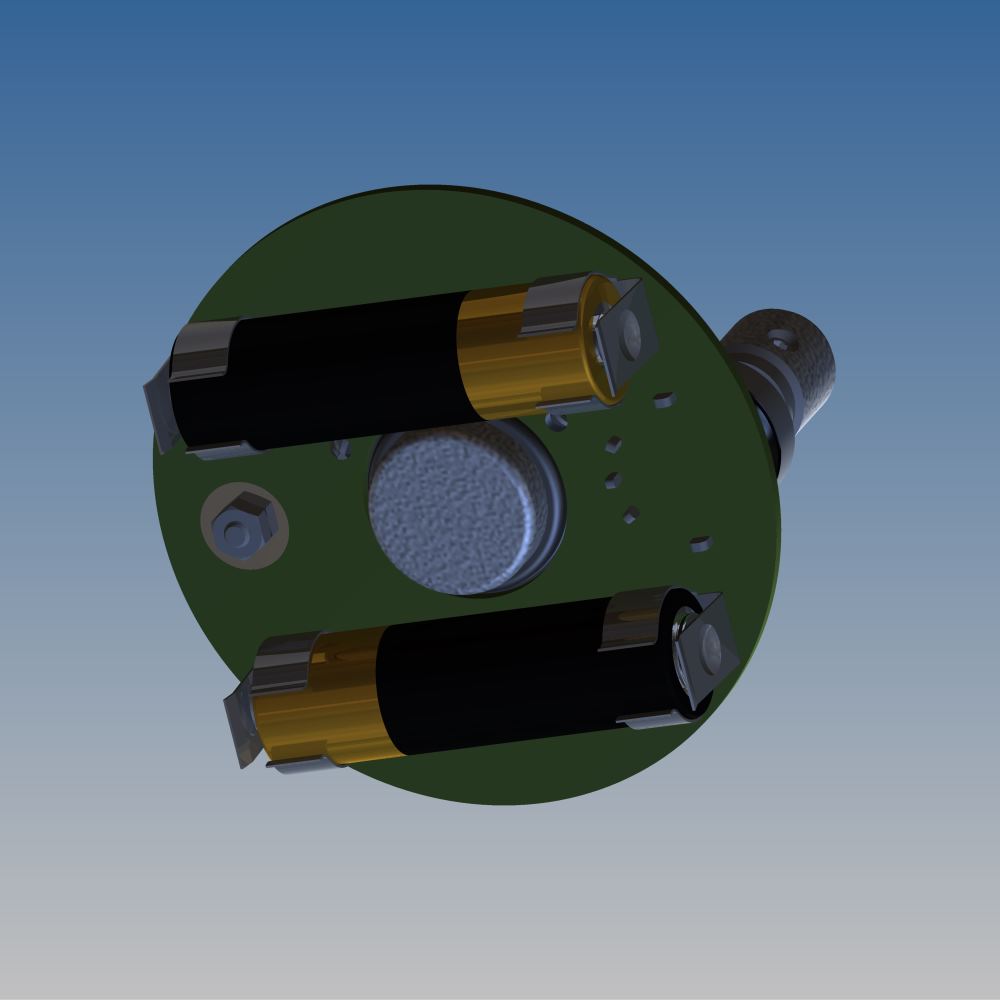

Learning new software is fun. This is me after a few hours playing with Materialise Magics 19 and SG+.

I've made a few modifications to the standard build:

- Changed the surface selection angle to 50°. This build is set up for laser metal powder bed fusion (aka DMLS), which will print angles a bit below that, and it's very possible that 50° isn't optimal.

- Changed the upper supports so that they're angled. In my last post you'll notice that if these are vertical, they'll rest on the bottom face of the cylinder. While that may be fine structurally, it means that I'd have that much more to clean up, and I think I'd rather have the supports go all the way down to the build plate instead. It's *possible* that this will reduce the amount of post processing necessary on the part - you'd need to run multiple builds with different configurations to be sure.

It's worth noting that this part is too far off the build plate right now - I'm still trying to get used to Magics' UI, and figured it didn't matter for now. I should probably also orient the part at a slight angle from vertical (see my recent post, here, for more details on this); again, I'll play with that a bit more later.

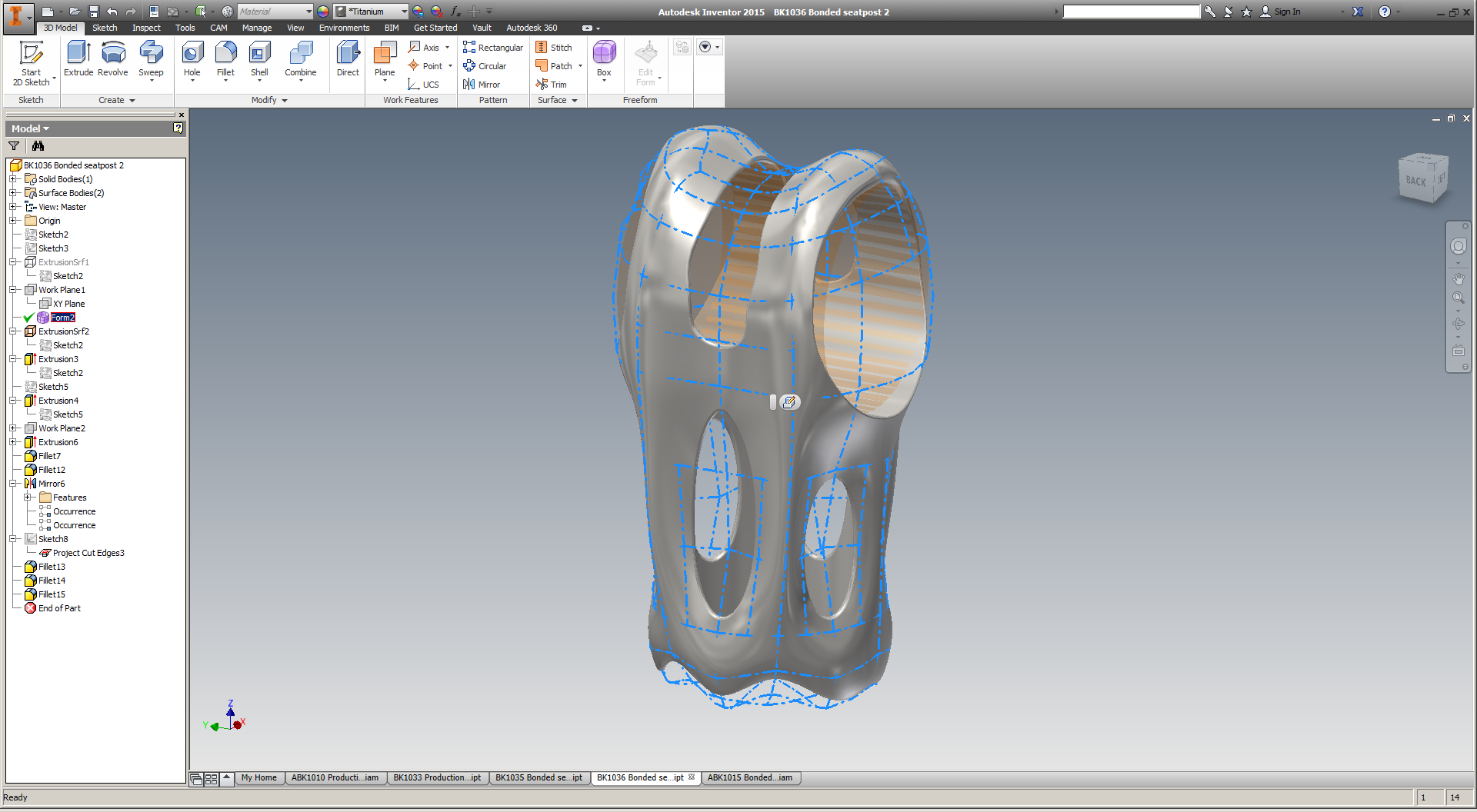

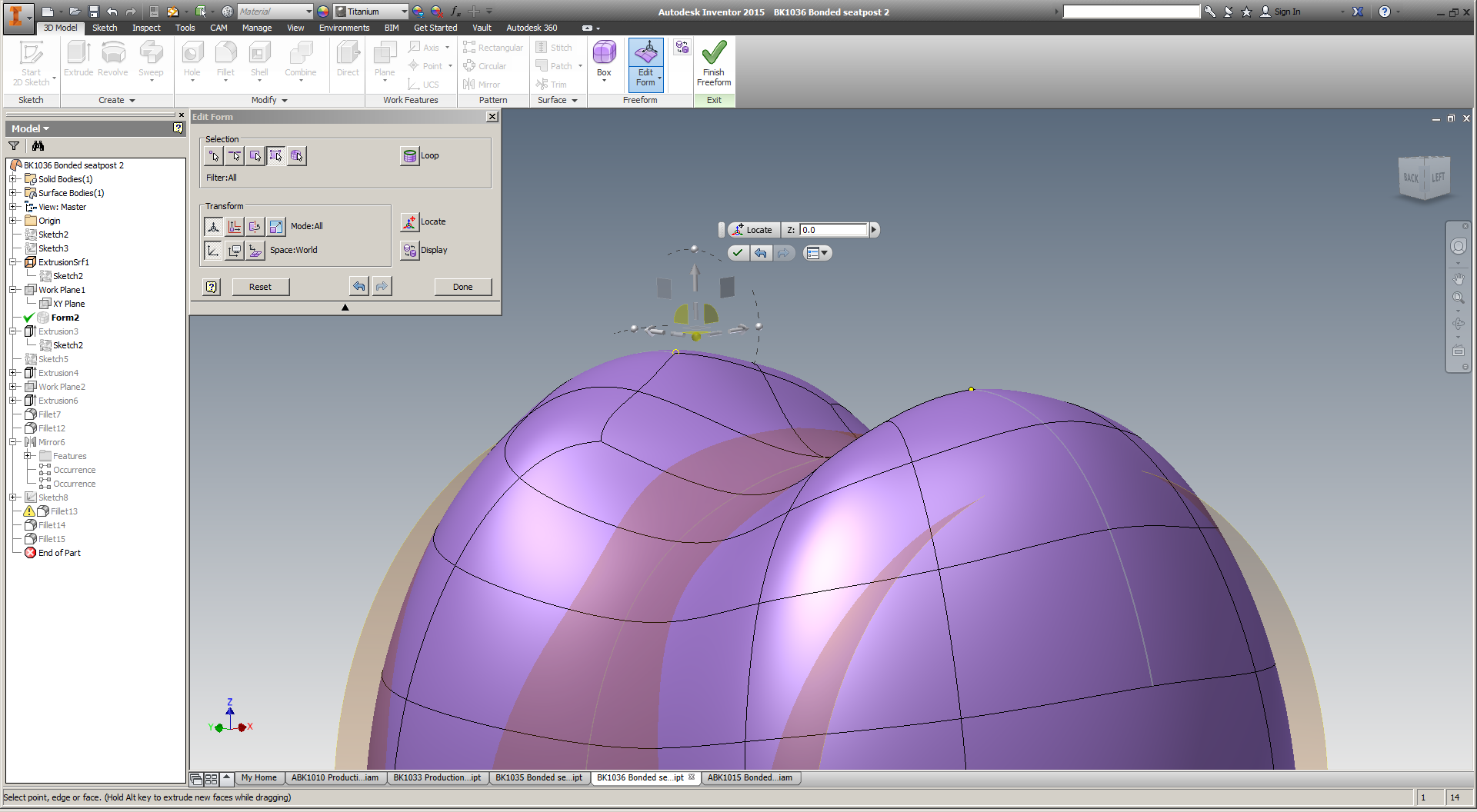

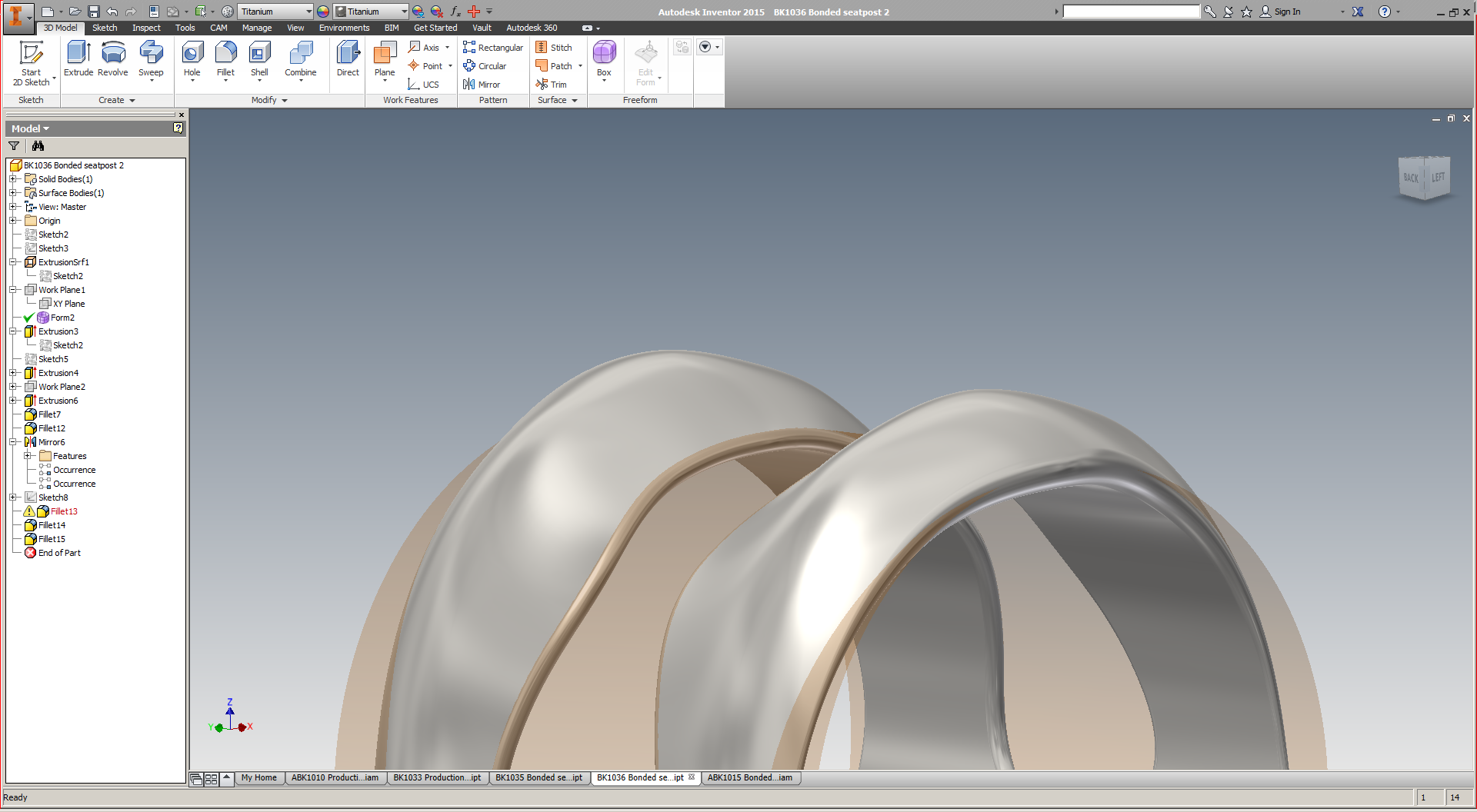

Oh, and I probably want to add additional reinforcements to the short ID, to make sure that it prints round. I'm looking at a few methods of doing this, most of which would require some work back in solid CAD (Inventor), or *possibly* some volumetric mesh generation software (like nTopology).

I'm definitely still getting used to Magics' philosophical perspective on the additive process chain, too. I have some thoughts on what this is, but will play around more before I share them :)

Stay tuned.